Customer Work Order Overview

Work Order Overview Information Guide -> Customer Work

Order Overview

Typically, Work Orders bill repair jobs for customers. The Work

Orders can be used two ways:

- MANUAL WORK ORDERS

(the Work Order is manually completed then entered into the

software):

- Use a pre-numbered preprinted Work Order

- Shop staff manually writes on the Work Order the amount of

labor, the part numbers etc used to complete the job - shop staff

does not need to look up the prices of the parts

- When the job is finished, it is entered using the number on the

Work Order instead of the Auto Assign number. The operator types in

the part numbers and the software finds the selling price, and

relieves parts inventory.

- After the Work Order is entered, the Work Order can be printed

out for the Shop Manager to approve the totals, before proceeding

with the final billing.

- The Work Order is billed, creating an Invoice.

Advantages & Disadvantages:

- This approach works well in small to medium sized firms, where

parts inventory is not considered a significant investment

- This approach works well when shop staff are reluctant to use

the software. Instead, counter staff enter the Work Order and

create the Invoice.

- Parts inventory is maintained, however, it represents only Work

Orders completed.

- Job Lists of outstanding Work Orders cannot be maintained by

the software.

-

COMPUTERIZED WORK ORDERS

(the Work Order is completely done using the software):

- The Work Order is setup by the shop staff at the beginning of

the job, i.e. when the equipment to be repaired is received. The

software assigns the Work Order #.

- The Work Order is printed, describing the equipment to be

repaired and the work to be done. The printed Work Order is used in

place of a preprinted Work Order to manually write on the labor

used and any shop notes. These are typed into the computer

later.

- As parts are required, the Parts Department staff adds them

immediately to the Work Order on the computer, enabling the parts

inventory to be completely up to date at all times.

- When the Work Order is finished, the shop staff bill it,

creating the final invoice.

Advantages & Disadvantages:

- This is the better alternative for medium to large firms where

the parts inventory is considered a significant investment, and the

service department is very active.

- This approach works well when parts and shop staff both agree

to use the software.

- The parts inventory is kept completely up to date.

- The software can create Job Lists of outstanding Work Orders,

which help to organize and prioritize the work in progress. This is

needed for large service departments.

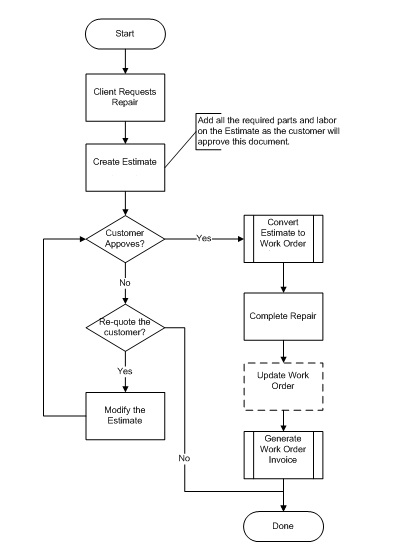

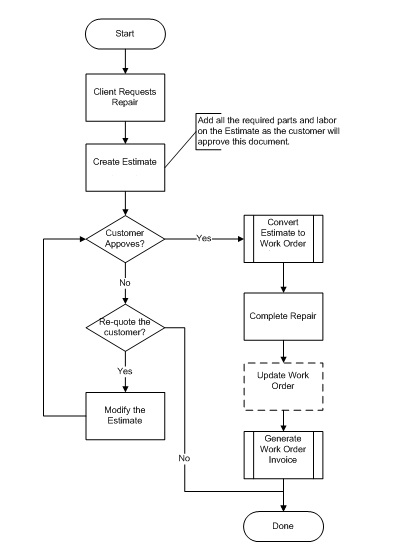

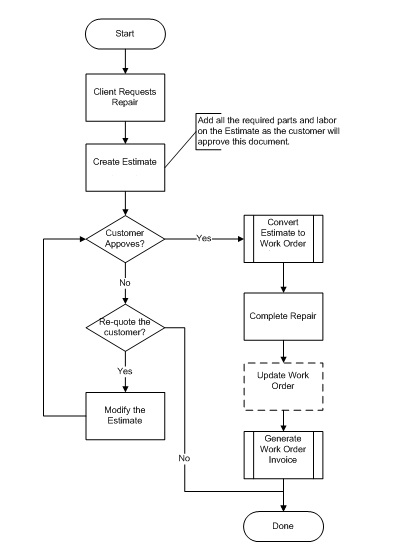

Process flow for a Customer Work Order:

Topic Keyword: WO000504