The Maintenance Schedules help to organize repeated maintenance

jobs on your equipment.

Once the products are setup in the Maintenance

Schedule based on date, or hours of use, or meter units, or

number of days on rent, or number of units used, then the

Maintenance reports can warn when that equipment is due for

service.

The Print Maintenance Schedule is

generally printed at the beginning of the week (daily for larger

service departments) to enable your shop staff to prioritize their

work load.

When a rental is requested for equipment due for maintenance,

the operator can be warned or blocked from rental on the contract

if the "Warn When Product Due for Maintenance" feature is

activated in the Company Contract

Parameters.

For complete details on the setup and use of this feature, refer to

Maintenance Due Causing Warn/Block on

Rental.

Then when the Work Orders are created

to service the equipment, the operator can select the procedures

and instructions due from the Maintenance Schedule.

When each Work Order is completed through Close Internal Work Order, the relevant postings

are generated, the schedule is updated and the repair history is

written.

A separate approach to track and ensure regular maintenance for non-bulk rental equipment is to use the Maintenance Work Orders utilities to automatically generate scheduled Work Orders to service non-bulk rental equipment that may or may not still be out on site.

When the Maintenance Schedule is used to enter the maintenance records according to service for individual products, the following utilities can be used to help setup the schedule:

There are three approaches to planning, tracking, and recording maintenance on fleet equipment.

Internal Equipment Maintenance: - standard

maintenance

Regularly print the schedule to identify equipment due for

maintenance. Then manually create Work Orders for the service and

on completion of service close Work Orders to update the

maintenance records, as follows:

Maintenance Work Orders: - auto creates

W.O. for non-bulk rentals

Generate an edit report on the equipment due for service based on

the Maintenance Schedules and the Job Site Interval days between

service, that can be used to automatically create the Work Orders

for non-bulk rental equipment only.

Then when the service is completed close the Work Orders to post

costs.

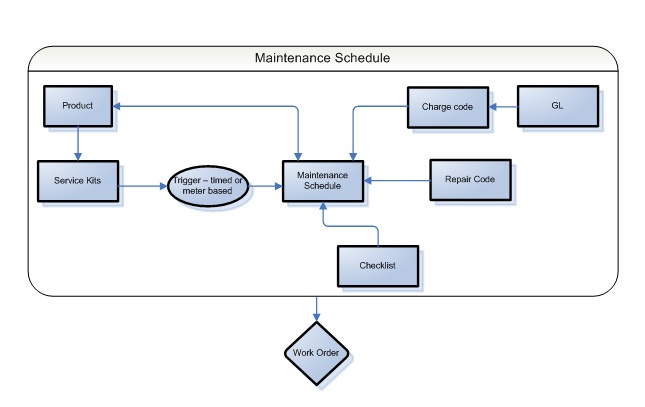

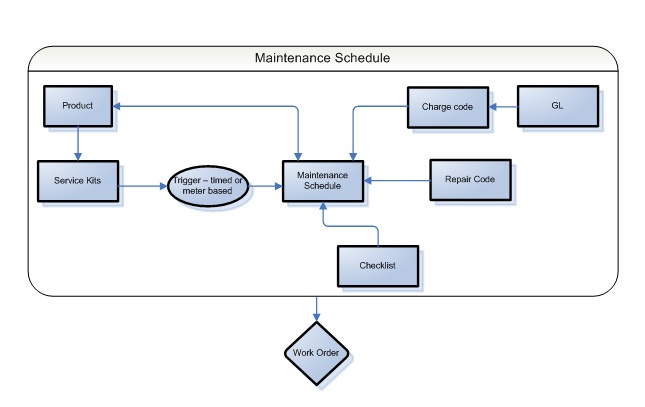

ERD (Entity Relationship Diagram) of Maintenance

Scheduling:

| Converted from CHM to HTML with chm2web Pro 2.85 (unicode) |