Inventory Receiving Overview

Purchase Order Overview Information Guide -> Inventory

Receiving Overview

TWO METHODS FOR RECEIVING INVENTORY:

When entering invoices for purchases of inventory, the following

two approaches are offered.

One must be selected company wide to meet your firm's business

practices.

- ONE STEP METHOD

- Update inventory count quantities and costs at the same time

when the A/P Invoice is entered.

- Pro: One step does it all.

- Con: Inventory is not updated as inventory arrives with

Packing Slip, but is updated later when the invoice arrives. This

means the software cannot reflect 100% accurate quantities on hand

at all times.

- Comment: This method works well in smaller or medium

sized firms, which don't have the staff available to handle the Two

Step Method. It also works well if the time period between the

receipt of the Packing Slip and the Invoice is small.

Refer to A/P Invoices for information

on processing inventory purchases without receiving the products in

the warehouse.

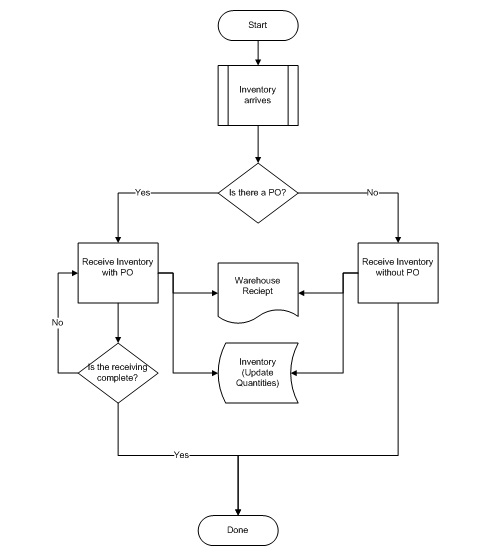

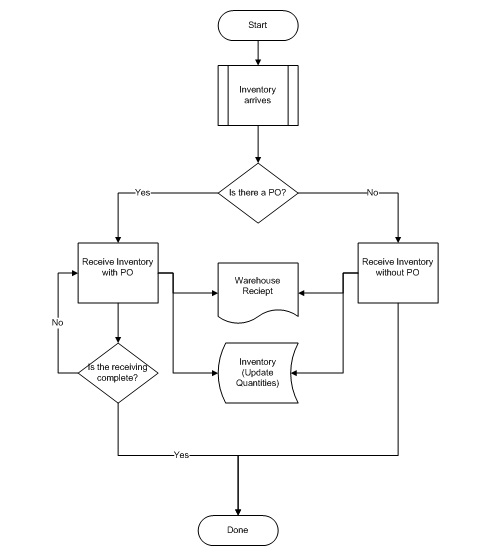

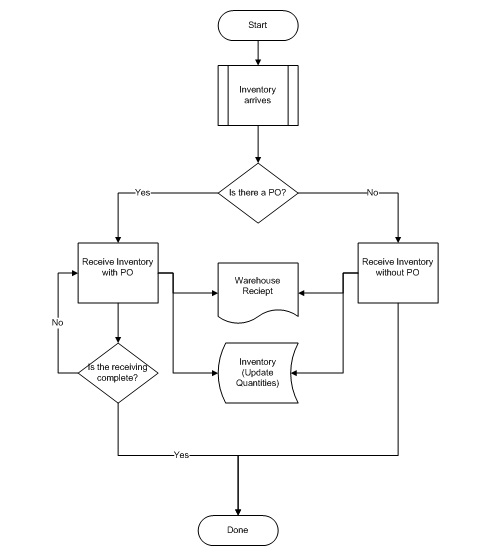

TWO STEP METHOD- Order new stock using a Purchase Order and update the inventory

count quantities when the products are received in the

warehouse.

Costs are later captured in a second step with the entry of the A/P

Invoice.

- Pro: Inventory quantities on hand are up to date.

- Con: It takes two steps, instead of one.

Depreciation cannot be completed until the A/P invoice has been

entered and posted.

Sale items average costs are not updated until vendor invoice is

posted to the General Ledger. Items sold before the invoice is

entered may not be reflect accurate Cost of Goods Sold.

- Comment: This method is required for large firms which

need strong inventory control. Inventory quantities are updated as

soon as new inventory purchases arrive, resulting in up to date

inventory quantities.

- Steps Include:

- Enter order in Purchase Orders.

Receive new inventory in Warehouse

Receiving.

Enter invoice in A/P Invoices.

Refer to Warehouse Receiving for setup

and processing of warehouse receipts.

The "One Step" or "Two Step" method best suited to your firm,

can be activated by the Inventory Received In Warehouse flag

in the Company Inventory Parameters.

Process flow for a Warehouse Receiving:

Topic Keyword: WR00